Products - Forks

QualityForks with ISO/ FEM/ITA suspension

Today the ISO/FEM-suspension

is world-wide the most common way of connecting forks to the lift-truck.

According to the rated truck capacity the ISO/FEM/ITA-standard

consists of four classes, each of them having a form A and B

(e.g. class 2A or 2B ).

The difference in the forms

A and B is the fork drop (clearence lower hook to floor).

All measures are defined in the international standard ISO 2328

Important notice:

For

more than 10 years the ISO/FEM/ITA-suspension has been an international

standard for most lift-trucks.

In the table below

the most important measures are listed.

| Class |

Rated lift-truck

capacity |

Load

centre |

Form |

Drop a

(clearence) |

b |

c1+1 |

c2-1 |

h1±3 |

h2+1,5 |

i1

min. |

i2-1,5 |

m1

max. |

| |

kgs |

mm |

ISO/FEM |

a=mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

ISO/FEM 1 |

0 – 999 |

400 |

1A |

76 |

331 |

16,5 |

16 |

394 |

306 |

14 |

13 |

31 |

|

1B |

114 |

432 |

|

ISO/FEM 2 |

1.000 – 2.500 |

500 |

2A |

76 |

407 |

16,5 |

16 |

470 |

382 |

14 |

13 |

31 |

| 2B |

152 |

546 |

|

ISO/FEM 3 |

2.501 – 4.999 |

500 |

3A |

76 |

508 |

22 |

21,5 |

568 |

477 |

17 |

16 |

40 |

| 3B |

203 |

695 |

|

ISO/FEM 4 |

5.000 – 10.000 |

600 |

4A |

127 |

635 |

26 |

25,5 |

743 |

598 |

20 |

19 |

47 |

| 4B |

254 |

870 |

| Class |

Rated lift-truck

capacity |

Load

centre |

Form |

Drop a

(clearence) |

b |

c1+1 |

c2-1 |

h1±3 |

h2+1,5 |

i1

min. |

i2-1,5 |

m1

max. |

| |

kgs |

mm |

ISO/ITA |

a=mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

ISO/ITA I |

0 – 999 |

600 |

1A |

76 |

331 |

16,5 |

16 |

394 |

306 |

14 |

13 |

28 |

|

1B |

114 |

432 |

|

ISO/ITA II |

1.000 – 2.500 |

600 |

2A |

76 |

407 |

16,5 |

16 |

470 |

382 |

14 |

13 |

31 |

| 2B |

152 |

546 |

|

ISO/ITA III |

2.501 – 5000 |

600 |

3A |

76 |

508 |

22 |

21,5 |

568 |

477 |

17 |

16 |

40 |

| 3B |

203 |

695 |

|

ISO/ITA IV |

5.001 – 8000 |

600 |

4A |

127 |

635 |

26 |

25,5 |

743 |

598 |

20 |

19 |

47 |

| 4B |

254 |

870 |

|

ISO/ITA V |

8001 - 11000 |

600 |

5A |

127 |

728 |

35 |

34.5 |

830 |

680 |

26 |

25 |

65 |

| 5B |

257 |

960 |

Specials are quickly made to order 'in-house'.

Please click

Get

a Quotenext to the product of your

choice.

Forklift Forks

|

*All forks manufactured form high grade certified materials.

*All forks fully heat-treated, quenched& tempered to give minimum yield strength of 825Mpa. Minimum tensile strength is 1000Mpa

*Welding processes certified in accordance with ISO 3834-2.

*All forks meet or exceed the requirement of the national and international standards ISO 2328, ISO 2330, ISO 3691-1, GB/T 5182-1996.

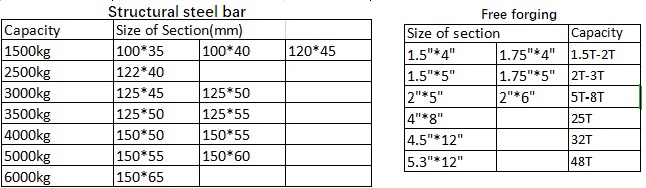

*They all can be made by free forging or structural steel bar. The forks of above capacity 7,000kgs is made by free forging.

Get

a Quote

Back

to top

|

Tube Forks

|

*All forks manufactured form high grade certified materials.

*All forks fully heat-treated, quenched& tempered to give minimum yield strength of 825Mpa. Minimum tensile strength is 1000Mpa

*Welding processes certified in accordance with ISO 3834-2.

*All forks meet or exceed the requirement of the national and international standards ISO 2328, ISO 2330, ISO 3691-1, GB/T 5182-1996.

Get

a Quote

Back

to top |

Roller Forks

Polished Forks

|

Special forks, fulll taper polished forks.It is special for food industry or chemical products.

Get

a Quote

Back

to top |

|